Rectangular Leonardo spaceframe

This page is about how to build a rectangular spaceframe

using angle iron - or similar material.

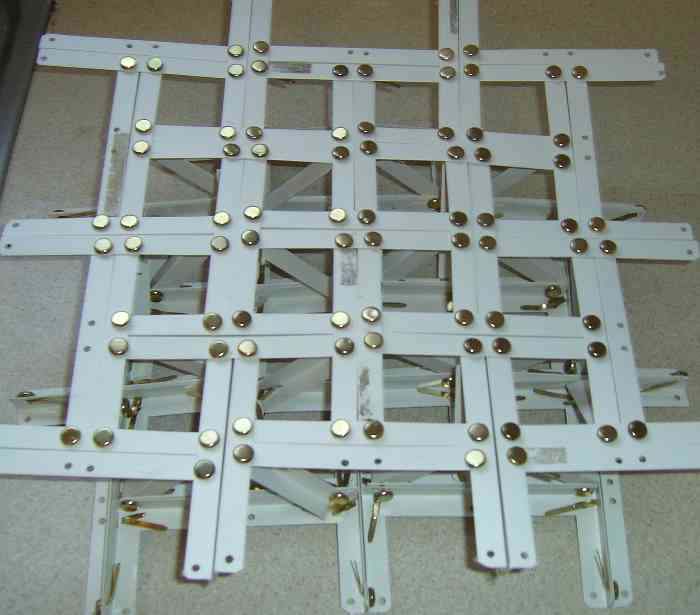

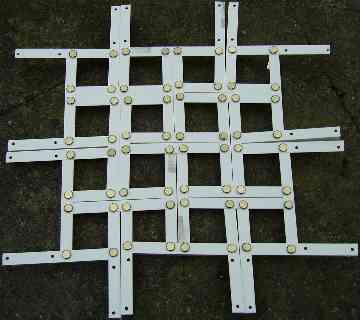

PVC angle model (plan)

|

The main attraction of using angle iron is that it is

inexpensive. It is one of the cheapest ways to buy steel

struts. It is the same material that is used to construct

electricity pylons.

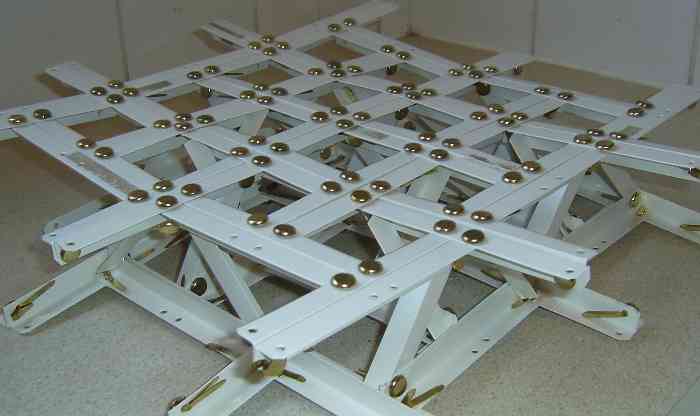

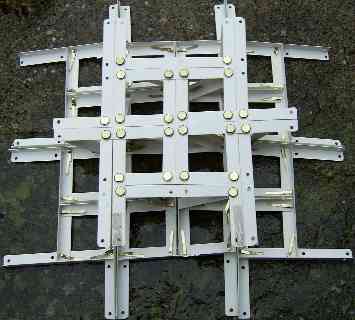

PVC angle model (front)

|

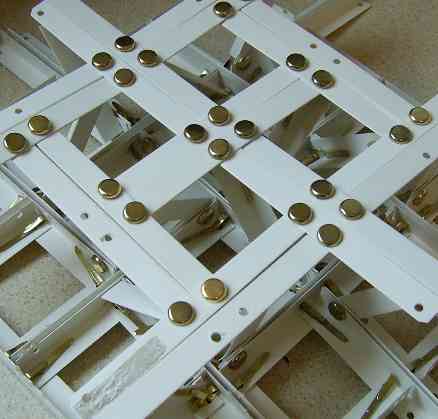

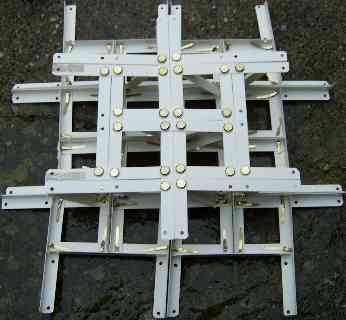

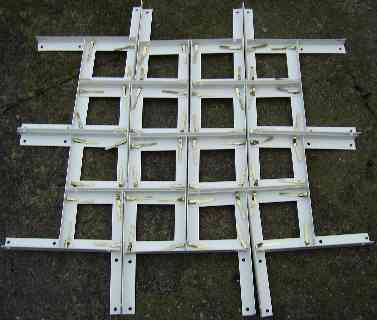

This page illustrates the layout using a model made of 12mm

PVC angle - and brass paper fasteners.

PVC angle model (under construction)

|

PVC angle model (isometric)

|

The spaceframe described here is based on a pattern by

Leonardo da Vinci.

It consists of two layers of "Leonardo" fabric, joined

together by connecting struts.

PVC angle (two layers)

|

|

PVC angle (two layers)

|

The model illustrated lacks diagonal support running from

the top left to the bottom right.

In theory the structure is vulnerable to sheering forces

that exploit this omission.

Stabilising elements could be added in to resist such

forces.

However, in many applications the framework seems likely to

be supported around its edges - so in practice, the omission

of these elements is unlikely to me much of a cause for

concern.

The spaceframe described here has two identical layers,

which are joined together.

One such layer is illustrated in the following two pictures.

PVC angle (one layer, top)

|

|

PVC angle (one layer, bottom)

|

The following diagram shows the relationship between the classical pattern

- as used by Leonardo da Vinci - and the one employed on this page.

Classical 2D rectangular pattern

|

|

The pattern with struts pushed together

|

Inspiration

The design is based around a few basic ideas:

- The classical Leonardo roof design can be constructed

out of angle iron;

- Such a construction is naturally almost flat.

Given materials with appropriate dimensions, it could be

made to lie completely flat;

- Two such fabrics placed back to back can be easily

connected together with more angle iron to create a

rigid, prestressed structural framework;

- The resulting structure plays nicely with simple angle

iron boxes - which themselves are highly suitable as modular

construction units.

Application

This pattern could be used in a number of ways.

It could be used to construct ceilings, floors

or trussed roofing planes.

Alternatively, it could find application in the construction

of entire rooms.

An attraction in the latter case is that the single-layer

Leonardo fabric is excels at spanning large regions - without

any other support.

That means that supporting struts between the layers can

often be cheerfully omitted. That fact makes it easier to

create rooms that span multiple cells - and to create space

for doors and other openings.

Strength

As with other spaceframes, the structure is suprisingly

strong.

Despite being make of plastic only 0.7 millimetres thick,

the structure easily supports my own weight when I stand on

it:

PVC angle model under pressure

|

Configurations

Each layer has a chequerboard-like characteristic, with

alternate squares being identical.

In the configuration illustrated squares lie over squares of

the opposite type. The advantage of that is that it permits

all horizontal struts to be identically drilled.

The configuration obtained by placing squares over identical

squares has some advantages in the context of making a

framework with cells the size of rooms. In particular in

such a framework, the cells may more easily be varied in

size. Making the cells of different sizes can be useful -

when some cells are destined to be corridors.

Shaped surfaces

Deliberately-sheared versions of this fabric may be used to

construct anticlastic curved surfaces - for use in the

construction of saddle-shaped rooves.

Domes are also possible in theory - using the "Leonardo"

ability of the fabric. The shape would be limited to the

shape generated by the equivalent "Leonardo" dome under

those circumstance.

Vertical support

The pattern is quite suitable for stacking. If stacked very

high, adding additional vertical support to the lower cells

may become advisable - due to the extra weight they have to

bear. There's quite a lot of scope for adding additional

vertical struts in the cells to improve weight bearing

characteristics.

If used in very tall buildings, adding vertical

girders is likely to prove necessary - to supplement the

weight bearing properties of of the structure.

Limitations

The pattern depends on the ability to flex each struct

through the thickness of its metal twice over its length.

Struts that are too short to do that are not suitable for

performing this construction with.

If you have stiff short struts there are alternatives.

Rather than using a leonardo-style fabric, consider

one of the following alternatives:

Aluminium angle (dense)

|

This dense pattern is a close match to the Leonardo layout described above.

The struts are cut shorter - and there is no need to bend the

struts.

Aluminium angle (sparse)

|

This pattern is much sparser than the other ones illustrated.

Advantages

Compared to the more traditional layouts illustrated in

aluminium, the Leonardo pattern uses fewer connectors -

through using longer struts.

The longer struts provide strength - and use of the Leonardo

pattern helps create a large span if struts need to be

omitted.

|